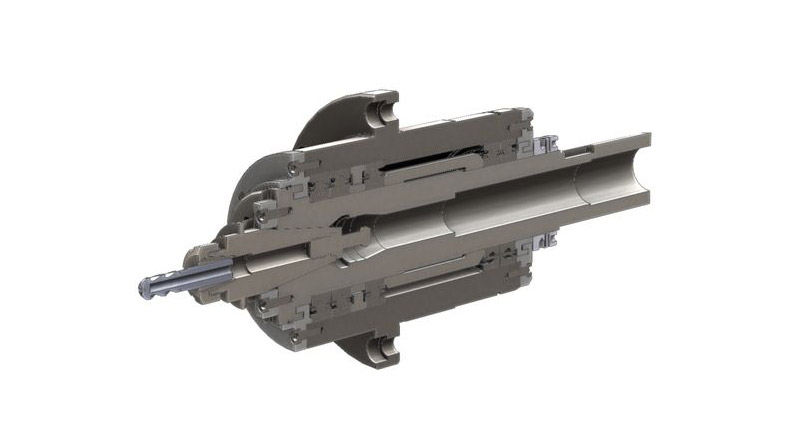

High-Speed CNC Spindles are designed to meet a variety of criteria. They must provide high rotational speed, transfer torque and power to the cutting tool, and have reasonable loading and life.

They must also be able to operate at various speeds and have minimal noise. This requires high-tech bearing technology, including precision-matched ball bearings and a rigid or elastic preload structure.

Precision

High-Speed CNC Spindles like those found at distributors like airturbinetools.com provide the machining precision needed for many applications. Whether you are machining steel, aluminum, or plastic, these machines will provide the accuracy you need to finish your projects on time and with quality.

One of the major reasons that spindles are a vital part of your machining shop is their ability to provide a wide range of cutting capabilities. This allows you to tackle various machining tasks, including milling, drilling, turning, and grinding.

The spindle is responsible for moving your cutter to the workpiece and delivering the power necessary to cut. An integral motor or a belt-driven spindle usually drives a spindle. These are the most common spindles available and can be used for various machining needs.

Another option is to attach an add-on spindle to your existing machine. This relatively inexpensive solution is often preferred because of its simplicity.

These can include a self-contained spindle or an attachment that connects to your existing spindle via a threaded adapter. These can be small routers, Dremel-like electric spindles, or air grinders.

In addition to increasing your machining speed, high-speed attachments, and spindle speeders are also designed to reduce machining chatter and increase your machining accuracy. This can result in shorter machining times and a better surface finish, both of which are critical in maintaining the integrity of your products.

The best way to determine your machining needs is to evaluate your current machine and decide if it will accommodate a higher-speed spindle. If you can’t upgrade your machining center, consider getting a new machine to accommodate your needed speed and feed rates.

Efficiency

High-speed CNC spindles have some applications, ranging from milling metals and plastics to machining for aerospace or mold manufacturing. They are also used in woodworking, electrical component creation, and many other fields.

Efficiency is one of the most important factors when choosing a spindle for your CNC machine. It can greatly affect how quickly you can complete your project.

The best spindles are designed for the task at hand, and they have a range of speeds to accommodate various materials and tools. This allows you to cut parts efficiently and effectively.

Another important factor to remember when selecting a spindle is the power rating. You need to ensure that the machine has enough power for your task.

When choosing a spindle, you should also consider its runout and how well the bearings are designed to hold up to high-speed use. For high-power applications, you should go with a spindle with ceramic bearings, as they can withstand intense heat without breaking.

In addition, you should consider the number of wheels on the spindle. This will affect the machine’s stability and help you achieve optimal results.

Durability

High-speed CNC spindles are a key component of your machine. They are designed to perform at extremely high speeds, so it’s important to choose one that is built for durability.

The purpose of a spindle is to rotate the cutting tool, which will then cut your material. A good spindle can make a difference in your shop’s productivity.

There are many different types of spindles available. Each is suited to a particular application and has its unique features. Choosing the right one can be challenging but worth the effort.

The power rating of a spindle is another factor to consider. A powerful spindle can remove more material faster than a low-power spindle. It’s also important to note that a higher-powered spindle will be more expensive than a lower-powered model.

A spindle comprises several components that work together to ensure maximum efficiency. These include the motor, the shaft, the bearings, and the lubrication system.

As with any machine tool, the selection of a spindle will depend on the specific needs and specifications of the machine it is installed on. While some criteria may seem obvious, the reality is that many are contradictory to each other, and a compromise must be chosen to create the best possible outcome.

Flexibility

High-speed CNC spindles are designed to perform multiple functions at once. They are also flexible and able to adapt to changing applications.

One of the main reasons that high-speed machining is so popular is that it allows you to machine parts quickly. This is because the rpm of the spindle lets you cut faster than traditional manual machining methods would allow, and it can also let your machine parts from hard or soft materials more easily.

In addition, this type of machine can be used to cut larger-diameter parts. This is because it has a large spindle capacity and a high-powered motor.

Increasing the speed of your spindle can increase your productivity, but it is important to choose the right speed for your particular application. The speed you need depends on the material you will be milling and the kind of tools you will be using.

Some materials require higher spindle RPMs than others to ensure that the material is removed properly and produces a smooth finish. For example, wood and plastics must be machined faster than aluminum or other materials.

For this reason, many manufacturers recommend getting a spindle with a wide speed range to cut both small and large-diameter tools simultaneously.

In addition, the spindle should have preloaded bearings to ensure it is rigid enough to cut hard materials without slipping. This will also help the spindle stay cool during high-speed machining.